A small proportion of the River Thames is to be illuminated using power generated by the flow of the river itself, as Kingston University tests prototypes of a new hydroelectric turbine design.

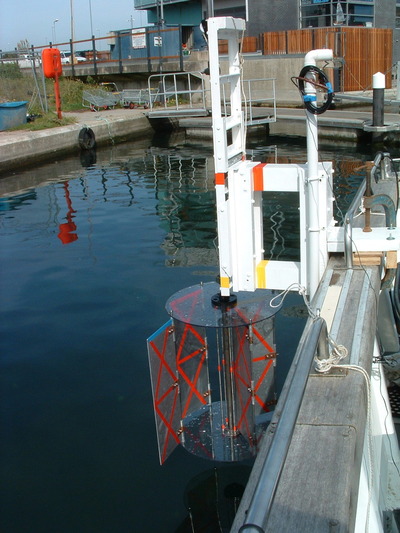

Based on the traditional water wheel, the new design is mounted on a vertical axis that sits on a pontoon. On this will be an array of test sensors and monitors, including a TorqSense wireless torque sensor from Sensor Technology Ltd.

The turbine under test has been developed by Hales Marine Energy near Eastbourne on the English south coast and is expected to be deployable in tidal seas as well as rivers. Designed to fit on a submergible tank, the turbine will sit on the sea bed and can be floated up to the surface when required. The unit under test is 1 m diameter and produces about 1 kW but the design is scalable — 5 m turbines suitable for inshore deployment would generate round 20 kW; smaller units would be suitable for river use.

With access to the test site being by small boat, Rod Bromfield, Senior Lecturer of the Faculty of Engineering, Kingston University knew that his test regime had to be both simple and comprehensive.

“The critical measurement is torque, as this indicates the power we can derive from the system. We had to be certain that we would get continuous measurements over an extended period of time, because we need to map power production against actual river flow. Also, for this technology to succeed in the emerging green power market it must be capable of continuous and predictable energy production,” Bromfield said.

One of the engineering issues that Bromfield faced was the relatively slow revolution of the turbine — in this test below 50 rpm. This helped define the choice of the TorqSense, but it is also a key feature of the Hales turbine — the slow speed means less stress on moving parts and therefore less servicing. It also minimises habitat disturbance, so that the ecological impact is low.

“When I contacted Sensor Technology I was very concerned about vertical mounting and harsh environment performance,” Bromfield said. “Fortunately there have been TorqSenses installed vertically, including several high up on vertical axis wind turbines, where they have to withstand gales, hurricanes and lashing rain.”

“To overcome the high resistance on the wheel blades that on one side are trying to move against the water flow, they are shaped and hinged to present a minimum resistance. The large blade area on the drive side produces very high amounts of torque (rotational force) at low speed, in the range of 10–20 rpm.

“Coupled with modern permanent magnet generators that can start producing electricity rotations as low as 2 rpm, my turbine can offer the possibility of tidal generation worldwide,” Bromfield said.

“Water is nearly 800 times denser than air so it carries far more energy, making water turbines a very attractive alternative to wind energy.”

The simplicity of the design, its robustness and low maintenance, relative ease of installation could also make it suitable for deployment in remote and less developed areas.

Image credit: iStock.com/SHansche